|

|

|

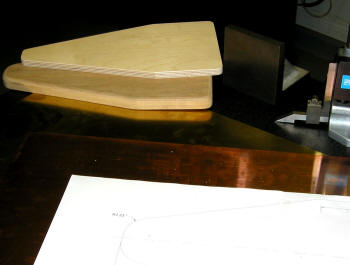

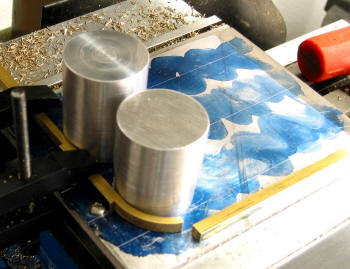

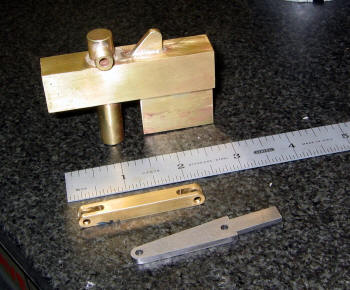

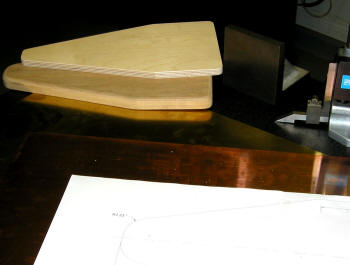

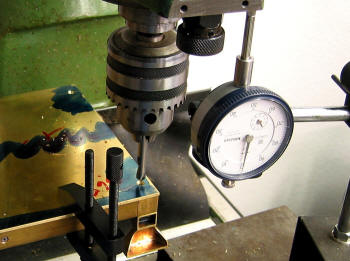

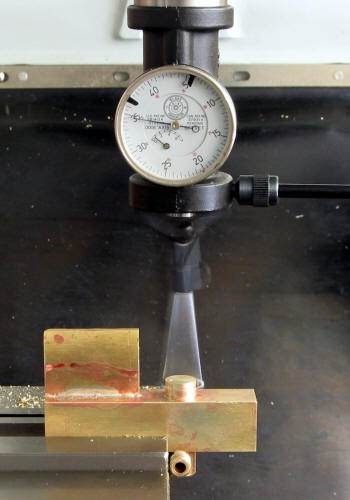

My neighbor made the former and backing

plate for me. Checked the dimensions with the surface plate and

gauge ... perfect! The Copper sheet is .04" and the 260 Brass 3/32"

is for the floor.

|

|

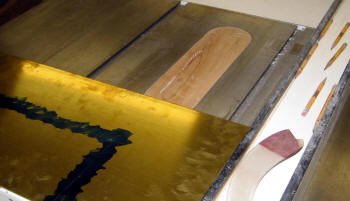

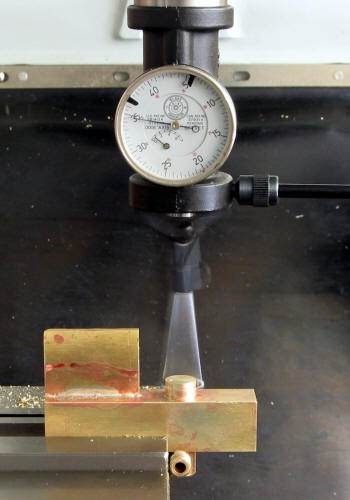

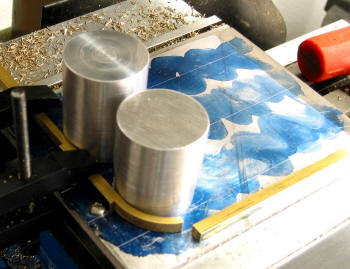

The height gauge is sitting on a

pair of V blocks which measured 4.905". Now cutting the copper

sheet to the required dimensions was easy. I used my bench sander

to smooth the edges and make the radius.

|

|

|

|

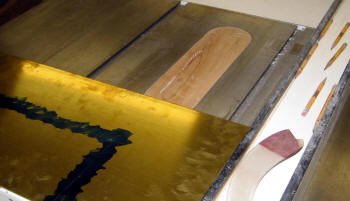

Same

neighbor has a table saw with a carbide blade ... cut through the

Brass plate very easily and was amazingly square. Then I used his 4

foot edge sander to smooth out the edges and the basic floor plate

was done ... ready to drill all the holes. But I am going to drill

selective holes ... I want everything to line up correctly!

|

|

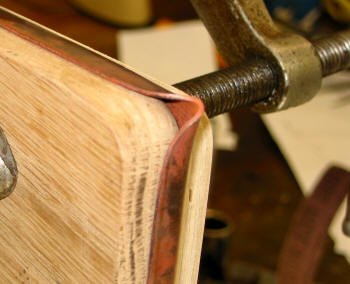

The copper side plate is ready to be annealed, it looks

funny here but it is actually symmetrical.

|

|

|

|

|

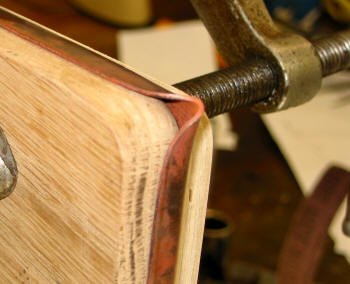

Annealed and I have started to form it ... this turned out to be a

lot easier than I thought. Just lightly hammered the edges using my

bright orange soft plastic hammer. |

|

This picture really shows what

not to do ... I should have

started closer to the rounded edge then hammer the straight edge.

It worked out okay as you will see later. I annealed the straight

edges twice and corners 3 times before I was finished. |

|

|

|

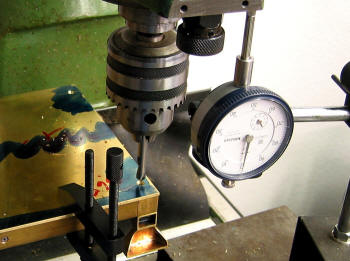

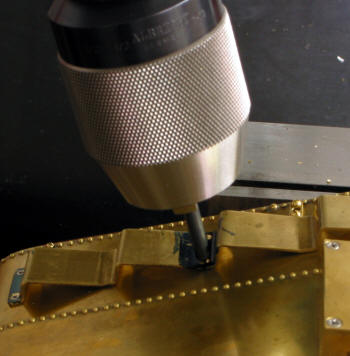

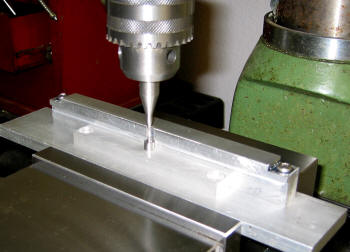

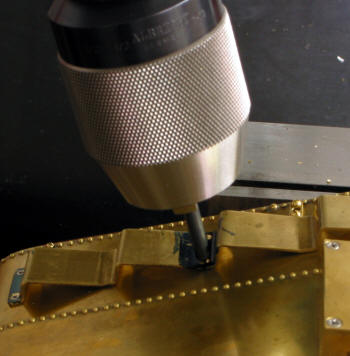

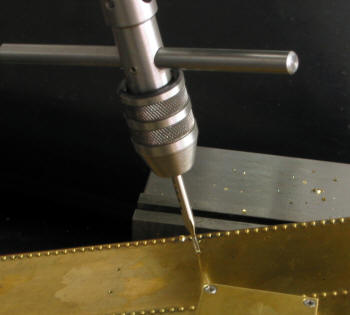

| To ensure a

perfect fit I attached the floor to the frame then center drill,

counter sink, drill and tap without removing the assembly. Each

hole was done the same way. |

|

Nice to have a vice that will clamp the whole frame. |

|

|

|

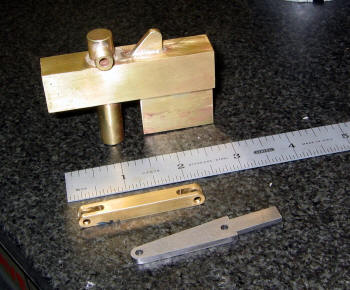

This is my fixture that I used to bend

the horseshoe braces ... multiple uses! Just change the aluminum

cylinders and I had a different radius. This bending was done

without annealing the Brass rod. As you can see it snapped. I

emailed Robert to find out if this was normal. Yep ... annealing

required.

|

|

Tried again ... this time I had

annealed the Brass to a dull red ... bending was so much easier. I

annealed it again to reduce some of the spring back ... I think it

helped a little. Those two screws prevent the bar from bowing out

... keeps it straight.

|

|

|

|

Each and

every counter sink hole was done with the mating part attached,

that way all mounting screws were located exactly in the correct

spot for re-assembly. Took more time, but was well worth the

effort.

|

|

Closer view of the bottom horseshoe. |

|

|

|

Top Horseshoe getting the second bend ... same fixture just

different attachments. Be careful on this radius ... Kozo provides

the outside radius ... here I needed the inside radius. Makes a big

difference when trying to get everything fitted.

|

|

This is the template that Robert

sent me for the Verge Board... glued to the brass sheet. Just cut

it with band saw and formed the curves with the table belt sander.

|

|

|

|

|

This arrangement provides the correct position to obtain the 15

degree tilt for the Verge Board. The block of Aluminum has a cutout

with about a 11.6 degree slant. We want the corners to be vertical

at the center of the bend. |

|

I again used the bending tooling

for the Vertical Board only with much taller columns. I thought

about trying using Kozo's method using sandwich plates for bending

... just didn't think I could do it ... so I used my fixture

method. The next step is to assemble the parts using 1-72 screws.

Here I'm making sure everything fits just right before I start

drilling holes!

|

| Update

9/12/07 |

Well it

has been a long time since my last update (5 months, where does the

time go?!). A lot has been done ... it's just that some of the work

is very detailed and takes a lot of time. Plus I acquired some new

equipment and that took away from the A3 project. Also I took a

Welding course at the local college ... to expend my capabilities.

|

|

|

|

Above I am taking some last measurements before I start soft

soldering the side plates. As you can see the Coal Bunker has been

assembled and secured with 1-72 screws. So it is also ready for

soft soldering.

|

|

Side panels soft soldering ...

completed. Looks messy and has too much solder. I used Oatey Solder

and H-2095 Water Soluble Flux so it is easy to clean. The only

problem with this solder is that it has a diameter of 1/8". I have

to get better at soldering before I start on the Top Plate.

|

|

|

|

More soft soldering ... think

I am getting better!

|

|

And better! Look at the bottom not the top! |

|

|

|

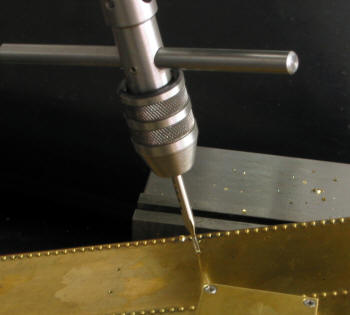

This is my embossing set up. The back guide is used to keep the

panel straight and set the distance from the rivet head to the

panel edge at .078" or 5/64" consistently for each and every rivet.

|

|

A closer look ... I tried to set the diameter of the die to

equal the spacing, but couldn't. So I ended up using the surface

plate and height gauge to scribe the location of each rivet ...

time consuming but it worked great. My spacing ended up at .1325".

I used this number so I would not end up have cutoff rivets at the

corners.

|

|

|

|

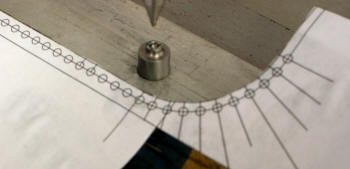

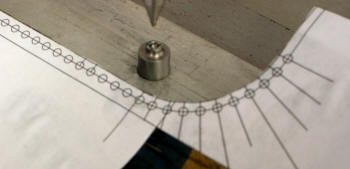

For the curves I made a drawing and pasted it on the Top Plate ...

no back guide here. I also set the depth of the die so that the

rivet height is about .025". I got that from Kozo's Building the

New Shay.

|

|

Finished embossing for now ... here cutting out the

rectangular hole for the manhole assembly.

|

|

|

|

The mounting flange for the manhole ... came from the Top Plate

cutout. See below for fitting ...

|

|

The beginning of the manhole cover ... a suggestion ...

pre-solder the plate and then the cylinder. Then heat together ...

it works much better than trying to heat the whole thing! |

|

|

|

I could not get the manhole assemble on the 9x20 chuck to cut the

flange to size. So I used a mandrel instead, also used it as a

former to get the tube inside diameter the correct size.

|

|

Here is one of those little hinges ... the radius must be

very close to .078" (5/64") otherwise the door won't open/close all

the way. |

|

|

|

Well I put the soldering off as long as I could ... in spite of its

looks, I am very please with the results. I was able to control the

amount of solder so that it did not overflow too much on the top

surface.

|

|

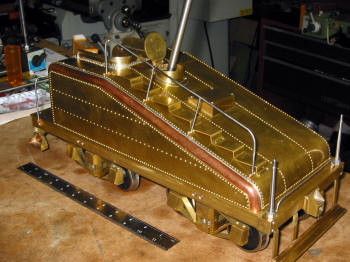

The Tender Tank really cleaned up nice! |

|

|

|

|

The finished Manhole assembly. Notice the rivets ... Kozo does not

show them on the drawing for the plate. But they are shown in the

various pictures. I like the looks as it maintains a continuity on

the Top plate. |

|

Close up of the Coal Bunker. |

|

|

|

Notice that solder came through just a little on the mounting

screws. By the way ... that little hole in the bottom plate ... an

earlier mistake. Later on I will fill the hole so that no one will

ever know it was there!

|

|

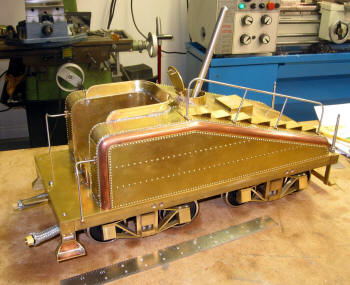

Almost done!

What is that in the background?

|

|

|

Still have lots to do on the tender...

Dummy Side Plates

Coal Stopper

Steps

Handrails and Handholds

Then I can move on to the Hand Pump and the Piping...

|

That copper and brass really shines nice.

|

|

|

Although

I still have lots to do on the Tender Tank I am looking ahead to

the Driver Wheels. In fact, I'm taking a Fabrication class at the

local College. There I will get some additional experience in the

machine area and CNC. I hope to make the Driver Wheels using CNC. I

have some machinable wax and 12" of 12L14. The big thing is they

have a Haas VF 1, 2, 3 and a new VF 4.

This ought to be fun!!

Until next time ....

|

| Update

12/10/2007 |

Since my

last update I've spent most of my time has been writing the G code

for the Drivers. I had a opportunity to use a Haas CNC machine at a

local college so I jumped ahead. So here are a few pictures showing

what was done on the Tender Tank: Dummy Side Plates, Coal Stopper

and Handholds.

|

|

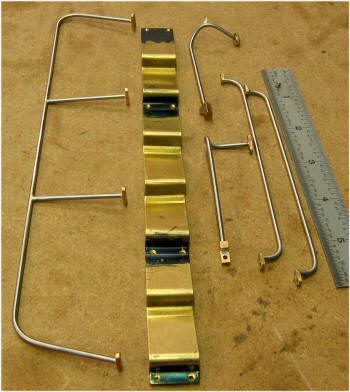

|

|

|

I used a print out from the Cad program to correctly size the Dummy

Side panels. There are actually two panels sandwiched together so

that the dimensions and curves will be the same for both sides. |

|

Not much to see here ... just

the Coal Stopper and part of the Dummy Side panel. I wonder if the

Coal Stopper is high enough, maybe I will go back a make it higher

when in actual use.

|

|

|

|

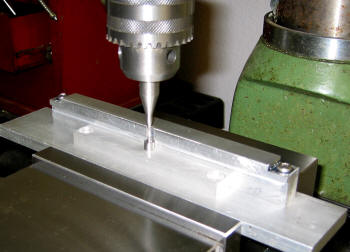

Pictured above is a 1/16" strip of sheet brass soft soldered to a

brass bar . The line in the blue layout ink is to locate the Y

coordinate on the CNC machine. These will be placed in a vice and

machined using the Haas CNC.

|

|

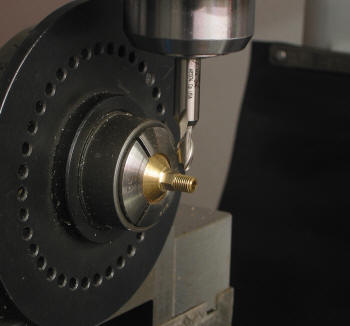

Just finishing the last Handrail

Support ... total 8 pieces of the 3 hole and 6 of the 2 hole. Took

all of 5 minutes to run ... won't say how long it took write the

program ... but it was my first hand written program ... no CAM

software. Just straight G code.

|

|

|

Still have a little more work on the Tender:

Handrails to bend and mount.

Machine the Handholds .... wonder if I can use the CNC lathe they

have ... that would be nice as I need four of them!

Mount the Steps.

The Hand Pump and Tender Piping\. |

A better view of the Dummy Side panel, the embossing was the same

shown before just a lot more ... glad I'm done with that for now.

The Steps still need to be finished and then mounted.

|

|

|

| Update

May 24, 2008 |

Time does

fly when you are having fun!! This update covers the remaining

build for the Tender, except for the Headlight and Painting. These

things will be done when the Engine completed (a

few years from now!). There are a few minor items that I may

change ... I will point out these later.

Note that all photos are thumbnails ...

click on them to enlarge then "Back arrow" to continue.

|

|

|

|

|

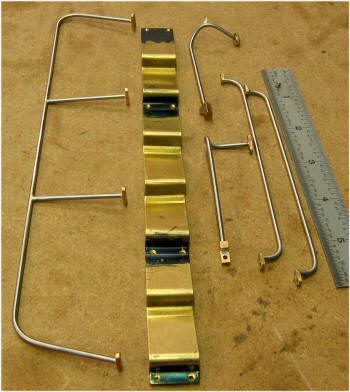

The handrails and stairs were not all that difficult to make ...

mounting them on the Tender was a bit more difficult. The hole

placement has to be just right. |

|

This seems a little extreme ...

but it did work! I didn't want to tilt the head too much so I

adjusted Tender some. I found out later that a friend had a right

angle attachment. With that I would not have to re-tram the head.

|

|

|

|

Same idea, but for the Stairs and Handrails not so much of a tilt.

Once I got the 1st screw in place I would drill the counter sink,

then the hole for the tap, move the Y axis over 0.531" and repeat

for the next mounting screw. Remove Stairs then tap, move back and

tap that hole.

|

|

This tap is for the Handrails pads. Used the same sequence

as I used for the Stairs.

|

|

|

|

|

Keeping things straight. |

|

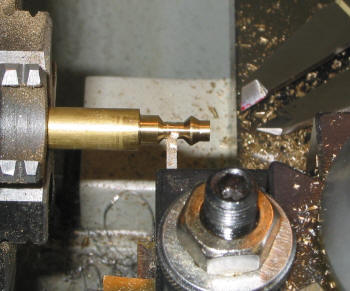

This is one of the Handholds

that was machined on the Haas CNC Lathe. Although the program was

simple and short ... the setup was not. After many trials (see next

photo) I found that I had to use the tailstock to support the long

thin hex rod. The extra material was needed because the tool had a

be a certain distance away from the tailstock. |

|

|

|

Sample of the trail and error results along with the almost

finished Handholds. As expected ... all four came out the same.

|

|

A close up ... not all of the machining was done on this

CNC. After this I took them home to finish them. |

|

|

|

|

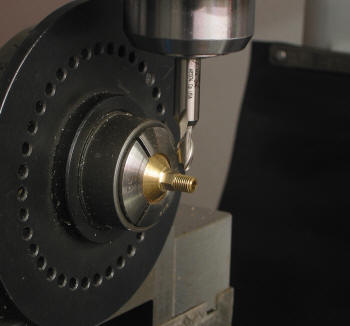

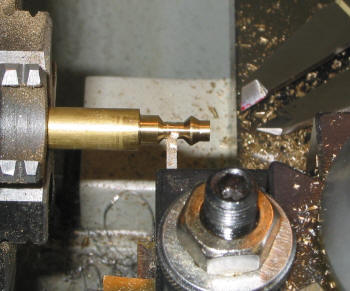

Getting ready to turn the diameter for the threads. Here I'm

setting the tool for the correct position. Once that is established

I changed to the other cutting tool. |

|

Simple enough ... |

|

|

|

And finally the rounding tip ...

|

|

Putting it all together... |

|

|

|

|

Getting closer... |

|

The Tender Pump along with Link

and the Lever (these were done on the CNC). I had a real hard time

with drilling the column ... had to replace it 2 times (stupid

errors). But once again I prevailed!

|

|

|

|

For some reason I was not able to fit the pump body in my lathe to

drill the valve top seat and the bottom hole. So I set it up on the

mill and used the co-ax indicator to find the center of the column.

|

|

I did a lot of turning on the opposite side with the lathe

in reverse. It was a lot easier to turn the taper .

|

|

|

|

Turning round stock into hex.

|

|

Parting off the small parts. |

|

|

|

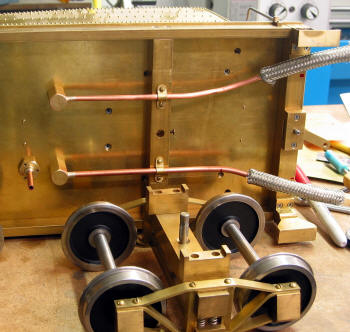

The collection of the Tender Piping. Notice I used the 5/32" tubing

from a local hobby store. The Suction Strainer ... I just could not

soft solder the brass screen. So I made it different ... not sure

that I like it just yet ... but it does work. Since I found Ed

Hume's "how to photos" I may try again.

|

|

To make a right angle bend in the small tubing I filled it

with Cerrolow a metal that melts at 117 degree F. I didn't use all

of the billet ... just a small section. I also made a holding

fixture with a small hole to let the air out while filling. And a

funnel that turned out to be too big and heavy. I will slim it down

next time. I only had ONE volcano eruption.

|

|

|

|

The finished pump, piping and handle. Notice the suction screen is

also not soldered. The removable screen idea is actually from

Kozo's Building the New Shay as an alternate way of securing the

screen. It works for me!

The pump works pretty good, the pressure drops down from 300psi to

150 real fast then very slowly to 90. I think the spring may need

to be a bit stronger.

|

|

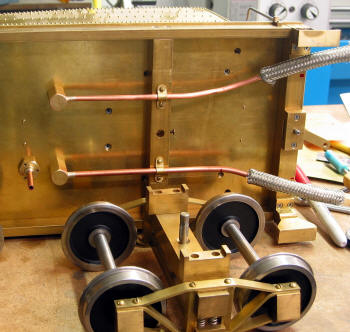

This is what the undercarriage looks like. I will finish

the brackets for the rubber tubing later when the Engine water line

are installed ... at that time I will know more of what is needed.

|

|

|

|

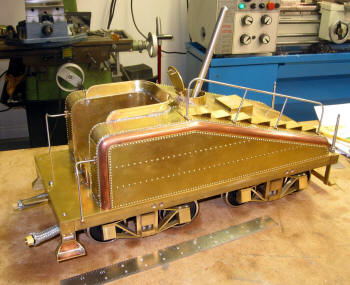

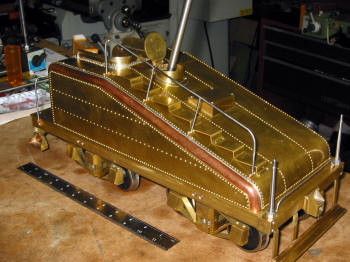

It's

finally done, well almost. I'm very happy with it ... only a few

things I might re-due.

Soon I will be ordering parts for the frame, finishing the drivers

etc.

Hope you have enjoyed the journey.

|